Choose language

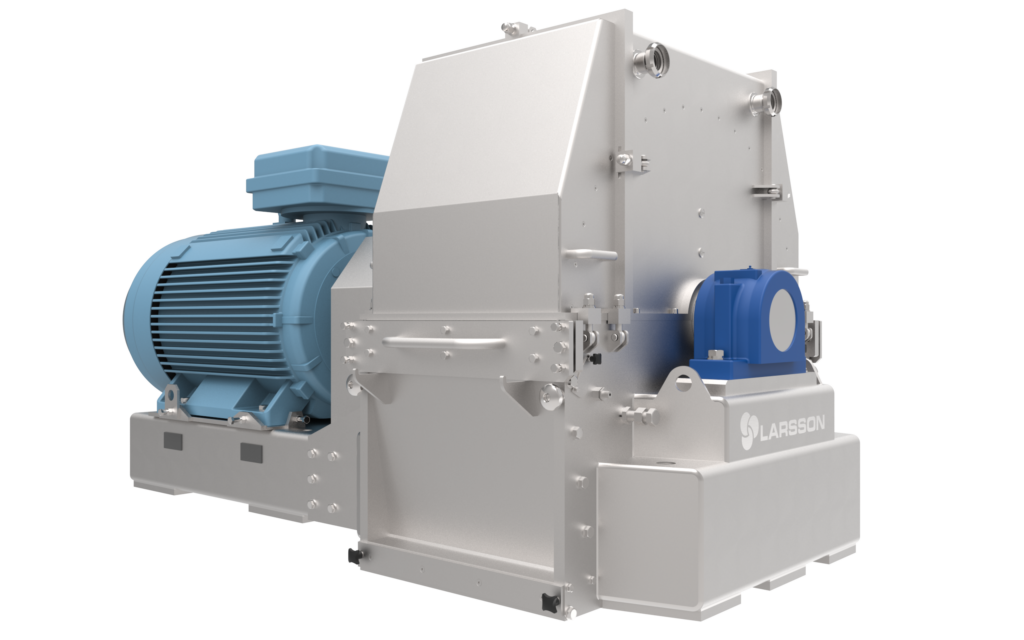

The Most Modern Rasper On The Market

Rasper

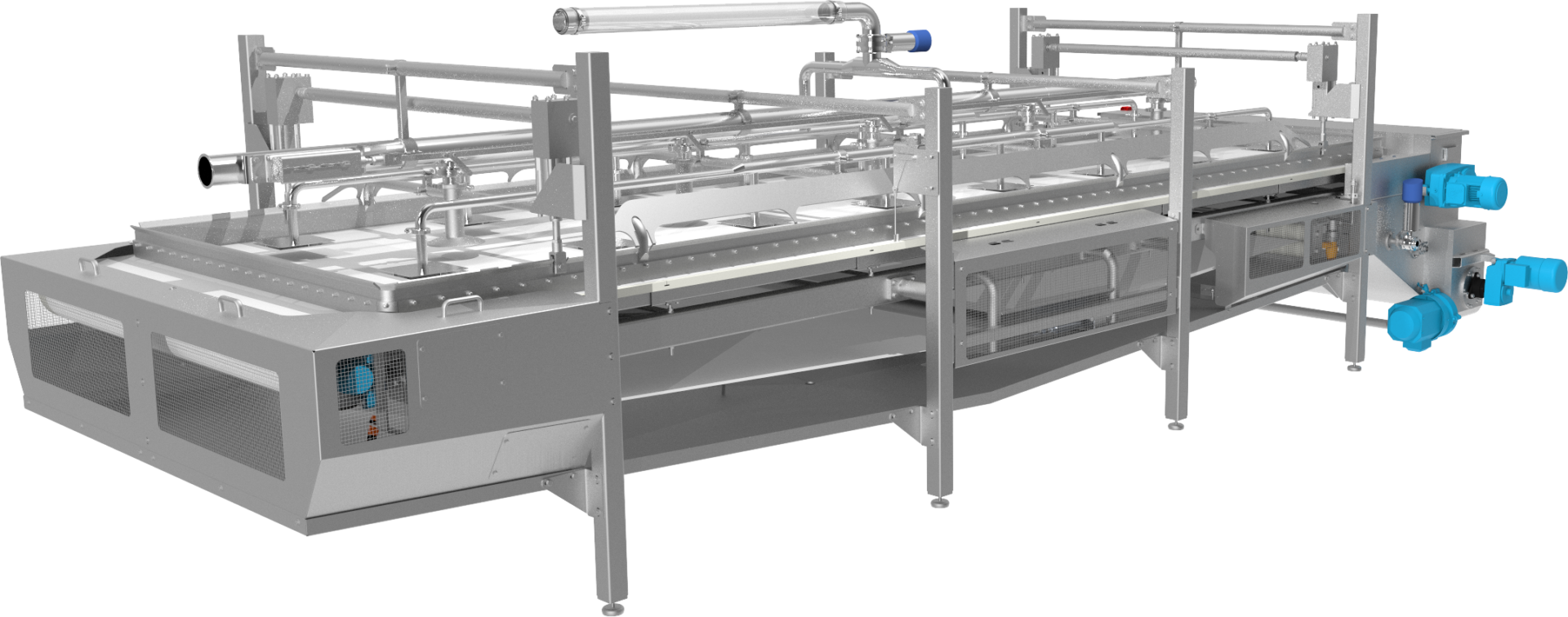

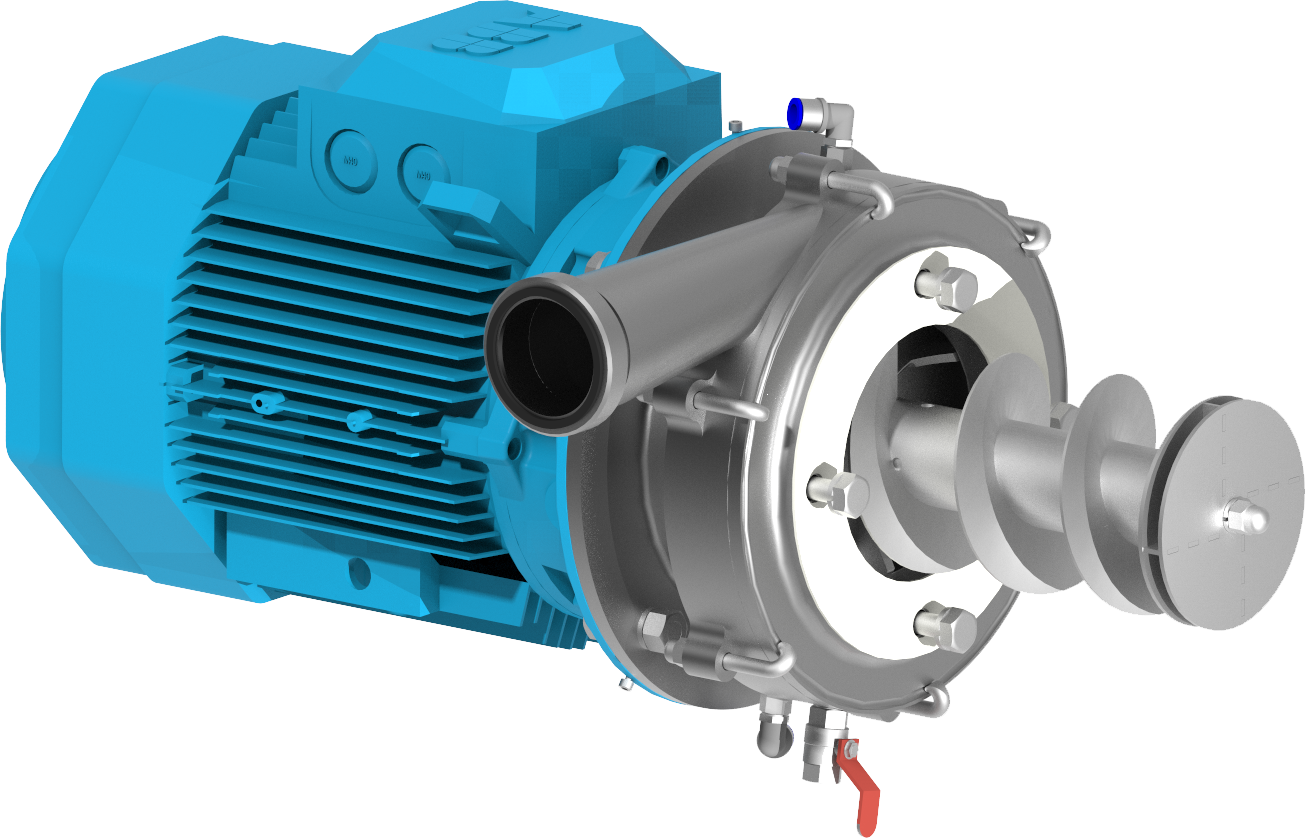

LARSSON releases a new design of the popular rasper. The slimmed design reduces weight and more service space around the rasper is obtained. The rotor design is kept by means of larger rotor diameter that incorporates the patented groove profile for the rasping blades. The profile makes it possible to place a greater number of rasping blades into the same diameter compared to the conventional profile. The rasping blades are clamped between two steel profiles, which allows them to be turned over or replaced rapidly.

With the large rotor diameter LARSSON is able to maintain the high velocity for the rasping blades at a lower motor speed. Several benefits are then achieved; reduced centrifugal force gives less stress in the material, greater number of rasping blades in the rotor increases the time between changing the blades and also increases starch extraction. Direct drive means less transmission losses and reduced power consumption. The LARSSON™ rotor is reversible which increases rasping blade service life.

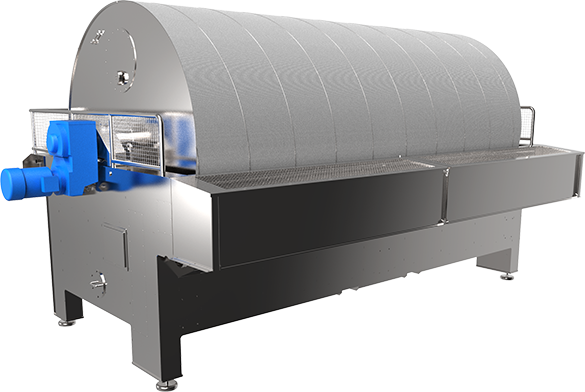

The new LARSSON design is also the most service friendly rasper on the market. Available in widths from 400 up to 1000 mm and motor sizes up to 500 kW.

LARSSON™ Rasper GL550/300 is specially designed for small capacities. The rasper is entirely made from stainless steel and fulfills the requirements of easy operation, maintenance and accessibility.